April 24, 2025 - 21:17

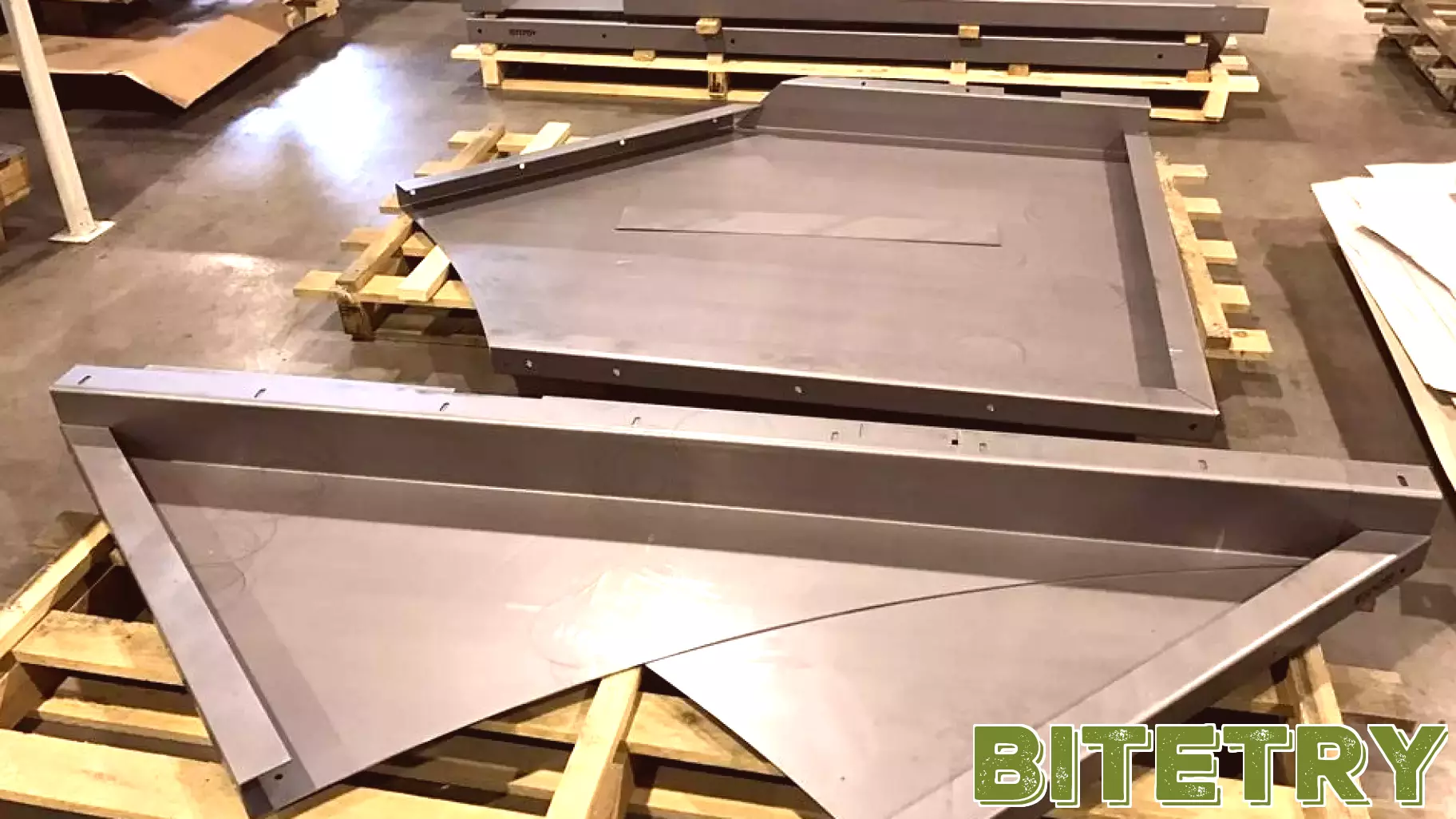

Metal fabricators looking to improve the efficiency of bending large workpieces should consider modern folding technology. This innovative approach offers significant advantages over traditional methods, allowing for greater precision and reduced material waste. By utilizing advanced machinery and software, fabricators can achieve complex bends and folds with minimal manual intervention.

The latest folding machines are designed to accommodate larger dimensions, making them ideal for industries that require the fabrication of oversized components, such as construction and automotive. These machines not only streamline the production process but also enhance the overall quality of the finished product.

Additionally, the integration of automation and digital controls in folding technology reduces the likelihood of human error, ensuring consistent results across multiple batches. As the demand for large-scale metal fabrication continues to rise, adopting modern folding techniques can provide a competitive edge, enabling businesses to meet client specifications more effectively and efficiently.